Own toolmaking (in-house)

Punching technology

CNC - Milling/Turning

Laser technology

wireedm

Surface

Grinding

Bending

Welding

Heat treatment

Assembly

Die casting technology

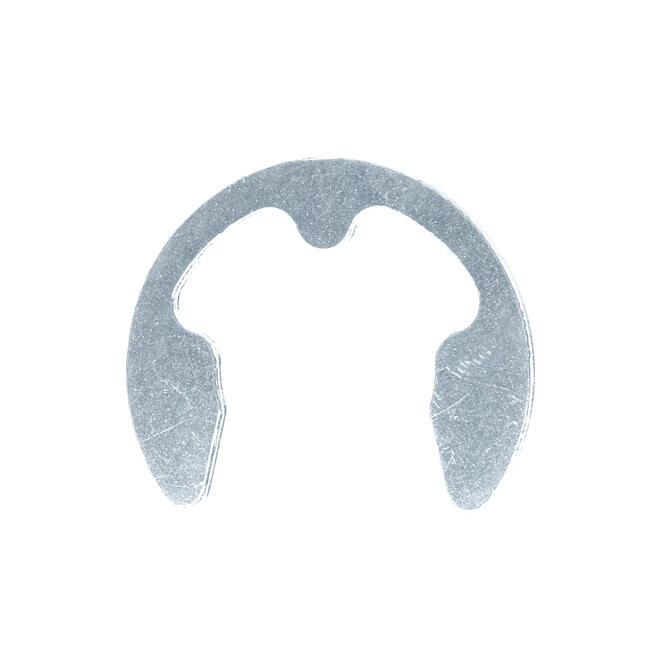

Punching technology

At Hugo Benzing, we rely on precise punching technology to ensure highest quality and maximum efficiency.

With state-of-the-art punching machines and innovative processes, we manufacture complex components for a wide range of applications. Our more than 90 years of experience and our deep technical expertise enable us to deliver the best solutions, perfectly tailored to the specific needs of our customers.

Fine blanking

High-speed punching

Precision punching

Deep drawing

CNC bending

High production speed

High precision

Low waste of resources

CNC milling and turning

CNC - Milling

The CNC milling at Hugo Benzing is a high-precision manufacturing process that enables the production of complex components with exact dimensions and fine surfaces.

Through the use of state-of-the-art CNC technology, high repeatability and efficiency are ensured.

Whether in series production or for custom manufacturing – Hugo Benzing offers tailored solutions for various industries, from the automotive industry to medical technology.

The combination of many years of experience and innovative machines ensures first-class results and highest customer satisfaction.

Complex geometries

Versatility

High degree of automation

CNC - Turning

The CNC turning at Hugo Benzing offers you precise and efficient solutions for the manufacturing of components in various industries such as automotive industry, medical technology and mechanical engineering.

With state-of-the-art CNC turning machines and high professional competence we guarantee exact results, both in series production as well as for custom manufacturing.

Trust in Hugo Benzing for high-quality, tailored components and optimized manufacturing processes.

High repetition accuracy

Complex shapes

High degree of automation

Laser technology

The use of laser technology at Hugo Benzing enables the precise and efficient processing of components for various industries. With modern laser systems, we offer customized solutions for cutting, engraving, and marking.

This technology ensures maximum precision, clean edges, and minimal material loss – ideal for complex geometries and demanding applications. Put your trust in laser processing at Hugo Benzing for innovative and cost-efficient manufacturing solutions.

Contactless processing

Highest precision

Versatility

Wire EDM

Wire EDM at Hugo Benzing is a high-precision manufacturing technology, ideal for the machining of hard materials and complex geometries. With state-of-the-art wire EDM systems, we achieve precise cuts and fine contours with minimal material impact.

This method is particularly well-suited for the production of tools, molds, and precision components.

No material distortion

Complex geometries

No mechanical load

Surfaces

The surface technology at Hugo Benzing includes a variety of processes designed to enhance the functionality, performance, and durability of components.

Trowalizing

Burnishing

Phosphating

Galvanizing

And many more

Grinding

A look inside our Grinding Center at Hugo Benzing reveals state-of-the-art technology for maximum precision and quality. With high-performance grinding machines and experienced specialists, we manufacture components with exceptional surface quality and precise tolerances.

Our Grinding Center is ideal for the machining of workpieces made from various materials such as steel or stainless steel. Whether for fine machining of tools, precision components, or series production – at Hugo Benzing we provide efficient, customized solutions that meet the highest demands.

Good surface accuracy

Fine machining

High precision

Bending

Bending with System – Experience that Shapes

In the bending division of Hugo Benzing, we process wire and sheet metal into precise series components – backed by over 90 years of expertise and cutting-edge manufacturing technology.

In addition to the pure bending process, we offer numerous production-accompanying post-processing options. This enables our customers to receive fully finished components – immediately ready for use and perfectly tailored to their specific requirements.

Reliable production of complex geometries

Consistently high quality

Large-scale volumes

Heat treatment

The heat treatment at Hugo Benzing takes place in our in-house hardening shop – one of the largest and most advanced hardening facilities in Europe.

With sophisticated technology, we guarantee precise hardening, tempering, and other thermal treatments to optimize material properties.

Improvement of mechanical properties

Increasing the service life

Enables further processing

Welding

At Hugo Benzing GmbH, we rely on innovative welding technologies to ensure maximum precision and quality in production.

Through the continuous advancement of welding processes and rigorous quality controls, Hugo Benzing ensures that all products meet the highest technical standards and are durable and robust.

High strength

Low material costs

Versatility

Die casting technology

The die casting technology at our subsidiary Eisenmann Druckguss offers high-precision manufacturing solutions for complex components made of aluminum and zinc.

With modern die casting machines and extensive manufacturing expertise, Eisenmann Die Casting produces high-quality castings used in industries such as automotive, mechanical engineering, and electronics. Thanks to precise molding and short production cycles, we ensure efficient series production with consistently high dimensional accuracy.

Die-cast aluminum

Zinc die casting

Assembly

The fully and semi-automated assembly at Hugo Benzing utilizes advanced technologies and integrated testing systems to maximize production quality and efficiency.

We rely on state-of-the-art automation processes to ensure the precise and rapid assembly of components.

Integrated testing procedures ensure that all components meet the highest quality standards.