EDITORIAL

System-safe electromobility

Dear reader,

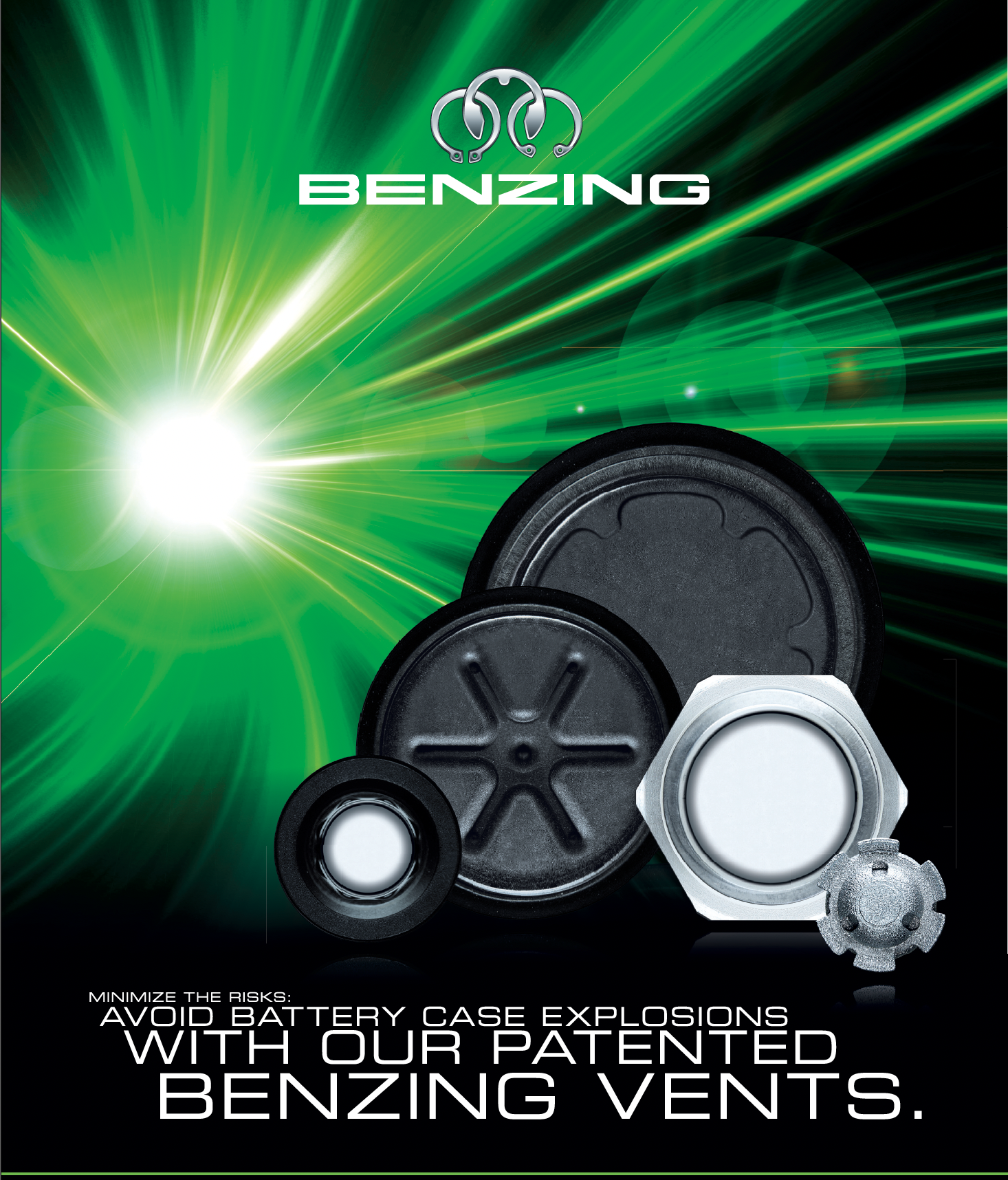

The success of electromobility is primarily due to the system safety of current high-voltage batteries. If they are thermally excited in such a way that a chain reaction could occur, the lithium-ion cells in hybrid and electric vehicles pose a high risk. This is an area in which the fuse element manufacturer Hugo Benzing, founded in 1933, has been successfully working for a long time. It all began in the early 1990s with valve technology for steering dampers, which, when installed in a hydraulic steering system, prevented shocks in the hydraulic circuit. The foundation stone had been laid.

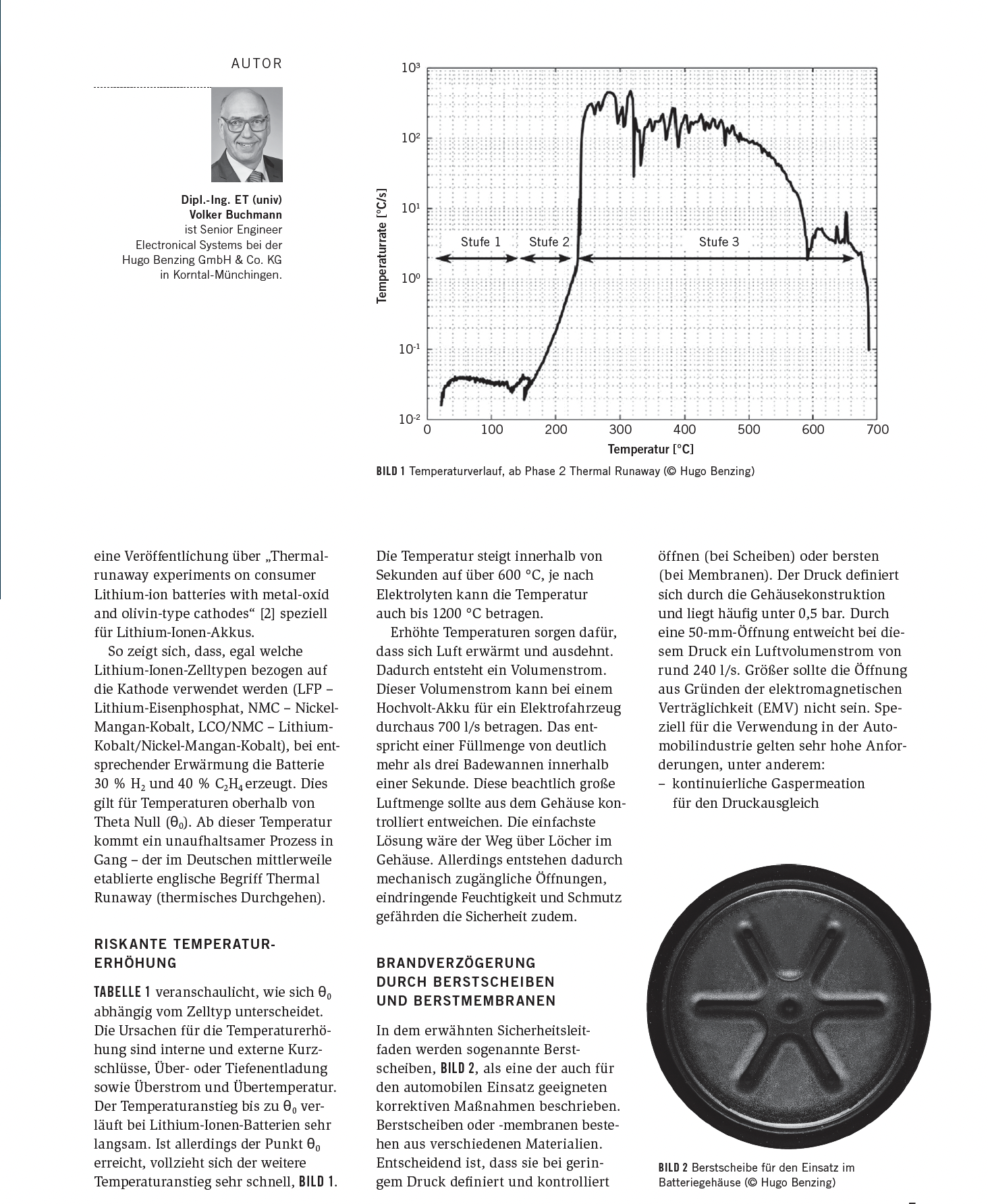

This was followed by further projects that focused exclusively on safety-related issues in the automotive industry. In addition to the development of special non-return, pressure relief and shut-off valves that prevent backflow in the oil circuit, Benzing’s engineers have been involved in the development of safety elements for a premium manufacturer since the early days of lithium-ion battery technology for fuel cell and electric vehicles. Over the course of time, a wide range of rupture disks and rupture membranes as well as pressure compensation elements have been developed through constant verification, which are suitable for all applications in lithium-ion batteries.

The company uses its experience in the field of safety-relevant products for high-voltage lithium-ion batteries to offer customized developments in addition to numerous applications with standard products. Hugo Benzing’s innovations are not only valued by some of the leading companies in the automotive industry, such as BMW, Bosch, Daimler, Ford, Getrag, GM, Porsche, VW and ZF, but the company, which is based in Korntal-Münchingen on the outskirts of Stuttgart, also has high-quality products in its portfolio for non-automotive applications.

I wish you a pleasant and interesting read.

Dipl.-Ing. (FH) Andreas Burkert

ATZ/MTZ correspondent